|

|

|

|

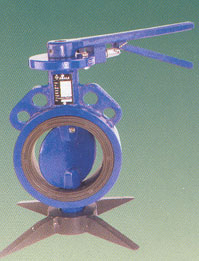

Butterfly

Valve |

|

|

|

FLOVELL Make Cast Iron Butterfly Valves

Cast Iron Butterfly valves are available

in a variety of materials suitable for

various applications in the marine,

water and process industries. The range

includes resilient seated and high performance

valves for chemical and corrosive areas.

We offer a range of lined valves with

special hygienic valves specifically

designed for the pharmaceutical, food

and beverage, and fine chemical industries.

Wafer type, double flanged bodies with

Replaceable seat is also available.

Butterfly valves are quick opening valves

that consist of a metal circular disc

or vane with its pivot axes at right

angles to the direction of flow in the

pipe, which when rotated on a shaft,

seals against seats in the valve body.

These valves are normally used as throttling

valves to control flow. Unlike ball

valves, butterfly valves do not have

any pockets in which fluids may become

trapped when the valve is closed properly.

|

Butterfly

Valves - Hand Level Operator

(Technical Data)

| SIZE |

A |

B |

C |

D |

E |

F |

H |

| DN-25 |

65 |

29 |

48 |

26 |

77 |

144 |

60 |

| DN-32 |

70 |

32 |

52 |

34 |

83 |

154 |

60 |

| DN-40 |

83 |

32 |

57 |

45 |

95 |

172 |

60 |

| DN-50 |

95 |

41 |

64.5 |

52.5 |

105 |

190 |

95 |

| DN-65 |

107 |

45 |

70.5 |

65 |

116 |

207 |

95 |

| DN-80 |

127 |

45 |

81 |

77.5 |

137 |

239 |

95 |

| DN-100 |

162 |

50 |

101 |

104 |

150 |

272 |

95 |

| DN-125 |

190 |

54 |

118 |

128 |

164 |

304 |

95 |

| DN-150 |

216 |

54 |

129 |

145 |

179 |

329 |

95 |

|

|

|

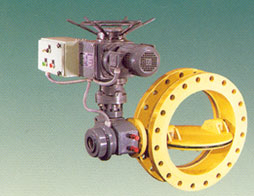

Butterfly Valves

Gear Operator

(Technical Data)

| SIZE |

A |

B |

C |

D |

E |

F |

H |

| DN-200 |

267 |

58 |

155 |

197 |

215 |

392 |

140 |

| DN-250 |

323 |

66 |

192 |

248 |

247 |

462 |

140 |

| DN-300 |

373 |

77 |

215 |

298 |

277 |

515 |

140 |

| DN-350 |

437 |

81 |

255 |

340 |

305 |

650 |

150 |

| DN-400 |

488 |

104 |

285 |

389 |

330 |

707 |

150 |

| DN-450 |

538 |

113 |

315 |

438 |

370 |

792 |

170 |

| DN-500 |

593 |

126 |

352 |

489 |

403 |

860 |

170 |

| DN-600 |

694 |

152 |

419 |

585 |

485 |

1022 |

270 |

| DN-700 |

806 |

167 |

470 |

688 |

560 |

1148 |

300 |

|

|

TOP |

Double Flanged Butterfly

Valves Gear Operator

(Technical data)

| SIZE |

A |

B |

C |

D |

E |

F |

H |

| DN-250 |

165 |

243 |

216 |

252 |

543 |

140 |

406 |

| DN-300 |

178 |

293 |

248 |

284 |

607 |

140 |

457 |

| DN-350 |

190 |

338 |

284 |

315 |

689 |

150 |

527 |

| DN-400 |

216 |

387 |

311 |

333 |

734 |

150 |

578 |

| DN-450 |

222 |

432 |

38 |

378 |

824 |

170 |

641 |

| DN-500 |

229 |

478 |

360 |

396 |

860 |

170 |

705 |

| DN-600 |

267 |

581 |

432 |

468 |

1017 |

270 |

825 |

| DN-700 |

292 |

675 |

491 |

527 |

1125 |

270 |

940 |

| DN-800 |

318 |

774 |

545 |

585 |

1247 |

270 |

940 |

| DN-900 |

330 |

873 |

612 |

702 |

1512 |

300 |

1283 |

| DN-1000 |

410 |

977 |

671 |

702 |

1512 |

300 |

1175 |

| DN-1100 |

440 |

1076 |

725 |

756 |

1643 |

320 |

1389 |

| DN-1200 |

470 |

1175 |

783 |

819 |

1782 |

320 |

1492 |

|

|

|

Typical

Fields Of Applications:

- Water treatment & effluent treatment

plants.

- Refrigeration & Air-Conditioning

plants.

- Sugar factories / Breweries

- Food Processing Industries

- Chemical / Petrchemical industries

- Seawater & Brine Pumping.

|

Technical

Advantages of the Butterfly Valves

- Excellent control characteristics.

- Tight shut - off even after

innumerable operations.

- 90 movement for full oprn /

close positon . Provision for

intermediatory locking after every

10 for regulation / controlling

purpose.

- Installation cost considerably

reduced because of very low weight

and component wear.

- No routine maintenance required.

- Longer life and reliable service

with minimum component wear.

- Renewable seats.No supplementary

gaslket required with the

adjucent pipework.

- Body & Steam totally protected

from service fluid.

- Centrally mounted disc, shafts

and bearings, therefore these

valves give higher CV values.

|

TOP |

Wafer Type Check

Valves

(Technical data)

| DN |

Dia 'A' BS - 10D |

Dia 'B' |

'C' thick |

| 25 |

68 |

14 |

15 |

| 32 |

72 |

17.5 |

15 |

| 40 |

81 |

22 |

16 |

| 50 |

95 |

28 |

16 |

| 65 |

108 |

41 |

17 |

| 80 |

128 |

52 |

17 |

| 100 |

158 |

76 |

20 |

| 125 |

190 |

100 |

21 |

| 150 |

216 |

122 |

22 |

| 200 |

272 |

158 |

27 |

| 250 |

333 |

203 |

32 |

| 300 |

383 |

248 |

36 |

| 350 |

442 |

266 |

40 |

| 400 |

492 |

305 |

50 |

| 450 |

555 |

360 |

50 |

| 500 |

613 |

402 |

63 |

| 600 |

724 |

486 |

68 |

| 700 |

837 |

590 |

72 |

|

|

| |

|

Wafer

Type Check Valves

Salient Features

- Simple but robust construction

with reliability.

- Pressure rating - PN - 10, PN

- 16.

- Range - DN - 25 to DN - 700.

- 100% tight shut-off.

- Short overall length - very

short space received.

- Suitable for flange standards

-BS,ANSI,IS,API etc.

- Material - C.I. / M.S. / CS

/ S.S.CF8 / CF-8 M.

- 'O' Rings - Nitrile / EPDM /

Vitron / Silicon / PTFE.

|

TOP |

Material Of Construction:

| Component |

Maerial Specification |

Optional Material |

| Body |

C.I. IS. -210 FG - 200 |

WCB - ASTM - A - 216,

CF8 - ASTM - A - 352,

CF8M - ASTM - A - 351, |

| Disc |

C.I. IS. - 210 FG - 200 |

WCB - ASTM - A - 216,

CF8 - ASTM - A - 352,

CF8M - ASTM - A - 351, |

| Shaft |

IS - 1570 Grade 40C - 8 |

AISI - 410, 304, 316 |

| Seat |

Nitrile / EPDM |

Neoprene / Silicon / Vitron. |

| Bush Bearing |

Self Lubricating Sintered

Bronze |

G.M. / PTFE. |

|

|

Technical Data:

| Manufactured: |

As per IS

- 13095 / BS - 5155 / AWWA -

C - 504 |

| Pressure

Rating: |

Pn - 10, PN

- 16 |

| Class |

125 / 150 |

| Temperature

Range: |

-20°

to +180° C |

| Face To

Face Dimensions: |

ISO - 5757

/ BS 5155 Wafer short / API

- 609 |

| Actuation

By : |

Hand leaver

- DN - 25 to DN - 150

GEar Operated DN - 200 to DN

- 1200 |

| End Connections: |

Wafer-Flangeless

Double Flanged |

| Suitable

for mounting flanges to : |

IS / ANSI

/ BS / DIN Standards |

|

| |

|

|

| TOP |

|

|

|

|

| |

|